Vegetable oils are chemically treated with alcohols to produce biodiesel, which has been fruitfully used as a diesel additive.

The mention of diesel brings an immediate mental imagery of an old truck emanating thick, billowing clouds of black smoke. And rightfully so… most refinements in diesel engines began only after the onset of regulations threatening their very existence.

The purpose of diesel engines, however, cannot be undermined in the transportation industry. While alternatives for gasoline exist in the form of CNG, LPG and ethanol blends, there are very few options for diesel. Amongst these is biodiesel, which is a concoction of vegetable oils.

Recommended Video for you:

Can Diesel Engines Run On Vegetable Oil?

Not only can they run on just vegetable oils, but animal fat and waste cooking oil as well!

However, before you think it’s perfectly alright to head to grocery stores instead of gas stations to run the same errands, there are a few things you should know.

The aforementioned oils cannot be added to the fuel tank of a diesel engine in their pure form. They must be processed further into ‘biodiesel’ and later blended with fossil fuel-derived diesel, before they can be used for internal combustion engines.

How Is Biodiesel Manufactured?

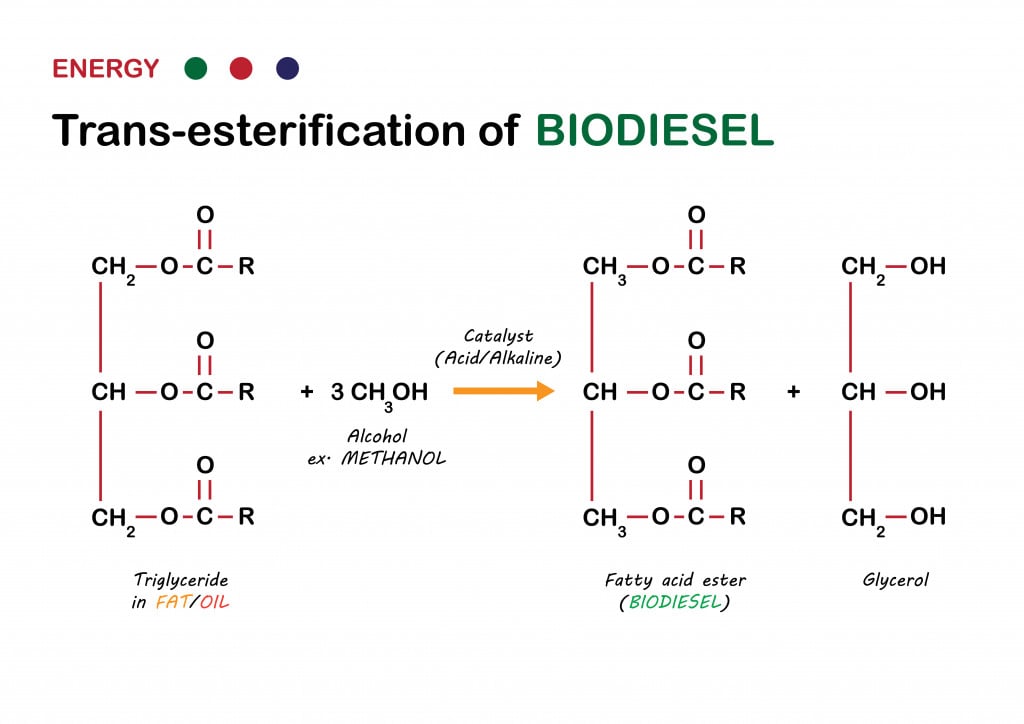

The process of manufacturing is based on the esterification of oils. Esterification refers to combining naturally occurring (organic) oils with an alcohol to produce ‘esters,’ along with other byproducts.

The fatty acids, or triglycerides, present in oil react with alcohols, such as methanol or ethanol, in the presence of strong alkaline catalysts like sodium or potassium hydroxide.

The chemical reaction manifests as a physical change where glycerol separates from the ester and is refined to be sold separately for its dedicated industry. The ester can be a methyl ester or an ethyl ester, depending on the alcohol used, and forms the bulk of the biodiesel. It is later blended with fossil fuel-derived diesel, also known as petroleum diesel, alongside additives that enhance combustion, lubrication, emission, and the longevity of fuel in storage.

What Kind Of Vehicles Can Run On Biodiesel?

Unless modified, most diesel engines cannot run on pure biodiesel. However, when mixed with petroleum diesel, biodiesel is compatible with most engines and fuel distribution systems. Biodiesel-blended fuel is identified with the letter B that precedes its percentage in the blend. Commonly available blends include B5, which refers to a 5% blend of biodiesel in conventional diesel fuel, and B20, where the proportion of biodiesel can range from 6% to 20%.

A B100 variety of biodiesels is also available, but it cannot be used without heavily modifying the engine. It is therefore used as a concentrate to be blended down with conventional diesel to produce B5 and B20 variants of fuel.

As of today, it has been observed that all diesel engines can run on B5 blends without requiring any changes to the engine architecture. This has resulted in the standardized circulation of low concentration blends.

Characteristics Of Biodiesel

Biodiesel has a calorific value of around 37 megajoules per kilogram, which is less than petroleum diesel, with a calorific value of around 45 megajoules per kilogram. Since they have comparable densities, more biodiesel must be mixed with petroleum diesel to generate the same amount of energy. Biodiesel has a higher cetane number than conventional diesel. Higher cetane numbers point to ease of combustion, and thus, the addition of biodiesel to conventional diesel increases the ease of combustion.

In a study conducted by Argonne national laboratories, it was observed that B100 contributes up to 74% less emissions than petroleum diesel. This is aided by the presence of oxygen molecules in the ester, resulting in near complete combustion. As a natural extension, lower blends like B5 and B20 have not only reduced the emissions of diesel, but also its consumption.

Advantages And Disadvantages Of Biodiesel

Other than a reduction in emissions and the improvement of combustion characteristics of standard diesel fuel, biodiesel presents some additional advantages. Biodiesel can be manufactured by locally sourced oils, reducing the dependency on imports. It is less toxic than diesel and gasoline, making it much easier to handle in the event of spillage.

The production of biodiesel has a positive energy balance. This means that it produces more energy than is required to manufacture it. Government bodies estimate biodiesel to provide 4.56 units of energy for every unit of energy consumed. However, biodiesel does have a few disadvantages. It is highly viscous at lower temperatures and can result in the clogging of fuel lines during winters.

It is therefore desirable to have a higher proportion of petroleum diesel in the mix at such times. If one has recently switched to biodiesel, its solvent nature dissolves buildup in fuel lines and may cause fuel filters to clog. Thus, changing the fuel filter during the initial cycles is important. It is also known to have debilitating effects on some parts of the engine, due to which modifications are necessary.

Is Biodiesel Really A Sustainable Alternative In The Long Run?

There are presently no clear answers to this question. This is because, unlike gasoline alternatives like ethanol and natural gas, biodiesel is an additive at best.

Though vegetable oil-based B100 and ethanol-based ED95 blends exist for diesel, they require heavy engine modification to the vehicle engines, which may serve as an impediment to their widespread use in the future.

References (click to expand)

- Life-Cycle Assessment of Energy and Greenhouse Gas Effects .... Argonne National Laboratory

- Emerging Fuels - Alternative Fuels Data Center. The United States Department of Energy

- Fuel Properties Comparison - Alternative Fuels Data Center. The United States Department of Energy

- (2008) Biodiesel CO2 emissions: A comparison with the main fuels in .... getec.unifei.edu.br

- A review: Advantages and Disadvantages of Biodiesel. irjet.net