Table of Contents (click to expand)

Fabric softeners contain cationic compounds (positively charged compounds) that bind with the negatively charged fabrics and nullify static cling, while the softness and scent is provided by the deposition of fabric softeners over the external fibers.

Just as no meal is considered complete without a dessert, no washing routine is considered complete without the final rinse cycle that incorporates the fabric softener. Through the built-in dispenser in our washing machines or via Downy, the adorable dispenser ball, fabric softeners are essential to keep our clothes soft as a cloud.

Also, as the cherry on top, fabric softeners help our clothes smell fresh and fragrant. Luckily, the list doesn’t end there; using a fabric softener also helps to avoid static cling, prevent wrinkles, make ironing easier, help fabrics retain color, etc. The question is, how does a mushy liquid used in generally tiny quantities achieve so much? Hint: It’s all about chemistry!

Recommended Video for you:

Why Are Fabric Softeners Used?

The purpose of using a fabric softener differs slightly depending on the method used for drying (and sometimes washing) one’s dirty laundry. While manually washing clothes is not a common practice in western countries, the use of mechanical washers puts a lot of stress on fibers, especially the fabric fibers on the outer surface. After washing the clothes, one may either choose to dry them out in the sun or use a mechanical drier, based on availability.

It is a well-known fact that air-drying your machine-washed laundry gives a harsher feel to the fabric, as compared to machine/tumble drying. Don’t believe me? Read about it for yourself: Why do clothes feel soft coming out of the dryer, but crunchy when they’re air-dried?

In the case of air drying, fabric softeners are primarily employed to retain the original softness of the material. As for machine-dried clothes that are already left softer, fabric softeners are used to avoid static cling and give the laundry a pleasant scent.

Static cling, as the name suggests, is the clinginess that develops in fabrics (and other items) due to static electricity. When in a drier or a washer, each piece of fabric comes in contact with several other types of fabric. While in contact, these materials rub and exchange electrons with one another, leaving each article either electron-rich or electron-deficient. Physically separating these materials leads to the generation of an electrical charge, a phenomenon known as triboelectric charging or the triboelectric effect (“tribo” means rubbing).

The development of static cling causes clothes to adhere/stick to the wearer’s skin, while also acting like a dirt and dust magnet.

Composition & Function Of Fabric Softeners

The softener solutions of the early 1900s (manufactured to diminish the harsh texture left behind from using primitive cotton dyeing processes) compromised water, soap, and a specific type of oil in a well-defined ratio (7:3:1). Advancements in the field of organic chemistry led to the development of better alternative compounds, such as quats, particularly dihydrogenated tallow alkyl dimethyl ammonium chloride (DHTDMAC) and more recently, esterquats and polydimethylsiloxane (PDMS).

Quaternary ammonium cations, more commonly known as quats, are essentially ammonium salts with a positively charged nitrogen atom at their heart, bonded to 4 different organic compounds. They can therefore be divided into two halves, one that is a water-insoluble (hydrophobic & fatty in nature) hydrocarbon end, and the other a water-soluble positively charged head. Since the majority of a quat molecule is hydrophobic, emulsifiers are added to assist in penetrating the wet fabric and for stabilization purposes.

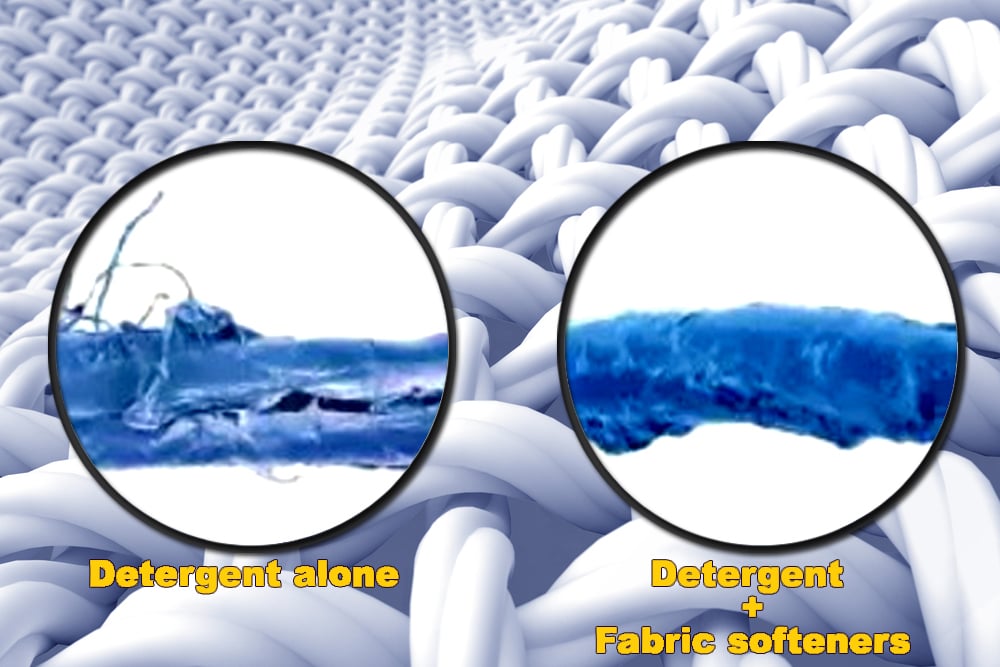

Currently, there are three different types of emulsifiers used in fabric softeners, namely micro-emulsions, macro-emulsions, and emulsion polymers. Each of these emulsifiers is added based on the level of fabric penetration/deposition to be achieved. Micro-emulsions allow for deep penetration into the fibers, while macro emulsions and emulsion polymers only deposit on the outer surface.

Once inside the fabric, the positively charged core of a quat neutralizes static cling by bonding with the negatively charged fibers. In the process, the threads stand up and a molecule-thick coating of quats is deposited over the external fibers. This coating essentially acts as a lubricating layer, owing to the fatty ends of the hydrocarbon chain in quats. The layer thus contributes to a fluffier and softer feeling material, along with making the ironing process notably easier.

In addition to quats and emulsifiers, other chemical ingredients and preservatives are added to enhance the color and leave the clothes smelling fresh and fragrant.

DHTDMAC, the traditionally used quat in fabric softeners, degraded quite slowly, leading to environmental issues, and was therefore superseded by a biodegradable alternative—esterquats. However, esterquats also possessed a few demons. The hydrophobic nature of the long hydrocarbon chains in quats caused a decrease in the absorbing capacity of items like towels and diapers. Manufacturers later found their solution in synthetic silicone compounds like PDMS, amine and amide silicones, silicone gums, etc.

Another very common question concerning softeners is why they can’t/shouldn’t be added along with the detergent itself. Since most fabric softeners contain cationic compounds (compounds with positively charged ions) and laundry detergents are anionic (compounds with negatively charged ions), the two can react to form an unwanted precipitate. However, the same isn’t the case with anionic fabric softeners, which can be added to the detergent itself.

Final Words

Now, to contradict my own words, using a fabric softener might not always be necessary or advised. People with very sensitive skin are prone to dermatitis (skin inflammation) when wearing clothes that have been treated with fabric softeners. Unfortunately, the ingredients in fabric softeners are also known to cause headaches and lightheadedness, along with some other very serious health issues, such as asthma and cancer.

Studies have further revealed that clothes, after being treated with fabric softeners, are also more susceptible to being set on fire. From an environmental point of view, softeners contain an ingredient derived from animal fats, while many of the chemicals used in softening conditioners are toxic and detrimental to marine life.

So, how can you maintain the softness of your laundry without using harmful fabric softeners? Try using wool or aluminum foil dryer balls to get rid of static cling and DIY-ing your own fabric softener by adding half a cup of vinegar to the final rinse cycle… and don’t worry, it won’t stink up your clothes!

References (click to expand)

- Toedt, J., Koza, D.,& Van C. K. (2005). Chemical Composition of Everyday Products. Greenwood

- Crackling Planets | Science Mission Directorate. The National Aeronautics and Space Administration

- Mishra, S., & Tyagi, V. K. (2007). Ester Quats: The Novel Class of Cationic Fabric Softeners. Journal of Oleo Science. Japan Oil Chemists' Society.