Table of Contents (click to expand)

Glue is made from organic substances and was discovered back in ancient times. The earliest evidence of glue was found in the cave paintings of Neanderthals in Lascaux, France. The raw materials for the production of glue might be animal parts or fish. The manufacturing process of glue involves cooking the raw material in water and then adding chemicals to make the glue into various forms.

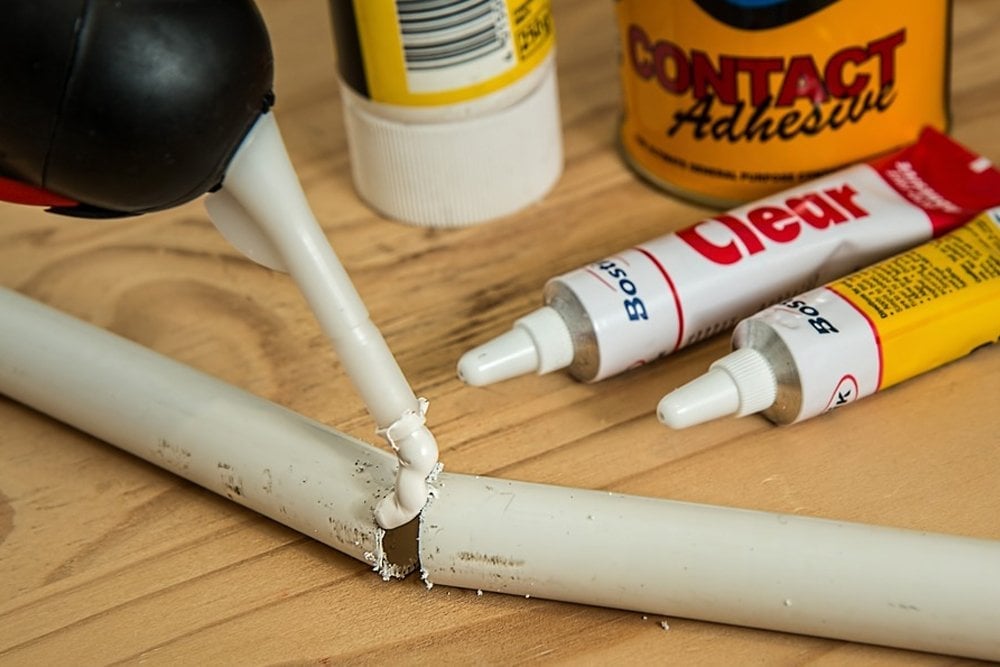

Glue is something we have all dabbled with since we were toddlers. The gooey and sticky substances are used to stick and join things together. However, glue is just a small part of the adhesive family. The difference between glue and other adhesive substances is that glue comes from organic substances, whereas adhesives are mostly chemically manufactured. The discovery of glue, in fact, occurred back in ancient times.

Recommended Video for you:

The History Of Glue

The earliest evidence of glue was found in the cave paintings of Neanderthals in Lascaux, France. These ancient artists wanted their art to last for a substantial period of time. To achieve this, they came up with an ingenious method of mixing glue with paint so that the cave paintings would be resistant to the moisture on the cave walls. Another area where glue is famously used is in furniture making. Although there are plenty of techniques to fasten pieces of furniture together, glue is most commonly used as the permanent binding element. Almost all the great cabinetmakers—from the sixteenth century to the late nineteenth century—used glue in their furniture construction.

In the 1930s, the boom of the chemical and plastic industries led to the development of a wide range of adhesives. The advent of World War II led to the flourishing of this industry, paving the way for chemically engineered adhesives, such as neoprenes, epoxies, and acrylonitriles. Such adhesives were primarily used only by the military, and were not widely available to the general public for daily consumer use. It was only made available to the public in the late 1940s. Since the introduction of glue to the consumer market, many more highly specialized glues have been made. Even waterproof glue has been developed, as well as other highly specific glues, including glues used for the construction of space shuttles! Glues are also used in industries as a part of colloids. Colloids are added to liquids to cause the solid particles suspended in the liquid to separate so that they can be recovered, either to clean the liquid or process the solids.

Raw Materials And Manufacturing Process

The raw materials used for the production of glue might not be what you imagine. Manufacturers typically obtain bones and the tissues of animals from slaughterhouses, tanneries, and meat packing plants. The world’s largest glue manufacturer is—not surprisingly—a dairy company known as Borden Company. The animal remains used as raw materials for the glue may include ears, tails, scraps of hiding or skin, scrapings from the fleshy sides of hides, tendons, bones and feet. Glue is not only made with animal products, but also with fish. The raw materials of fish glue include the bones, scales, heads and skins of fish from canneries and other processing plants.

The manufacturing process of bone glue, hide glue, skin glue and fish glue only has slight variations between them. The process begins with the washing of the hide, skin, bones and other animal parts. This is done so that any impurities or dirty particles are washed away. After this, it is soaked in water to soften it. This softened and clean material is known as stock. The stock is then passed through a series of water baths where the concentration of lime is progressively increased. This ensures that the skin or the hide of the animal swells up and breaks down. The swollen hides and skin are then washed in a washing machine to remove the residual lime present on them. Any final traces of lime are removed with the help of acetic acid or hydrochloric acid. Finally, the stock is put into boiling hot water and stirred, a process known as “cooking” the glue. The cooking process is either done in open tanks or pressured autoclaves.

Cooking this mixture at the right temperature and duration ensures that the stock breaks down into glue. If the temperature or timing is inaccurate, the glue will not come out at industry standard quality. The ideal temperature for most glue is 70°C. After the cooking process is performed three or four times, with an increase in temperature or pressure with every successive step, the resultant liquid is referred to as glue liquor.

The glue liquor is removed after it is formed and then reheated once again to thicken it. When the material is cooled down, it looks like a jelly. This form of glue still has one drawback—it may contain impurities. To remove the impurities and make the glue clear, chemicals such as alum or acid are added. After that, egg albumen is also added. These chemicals are added because they make impurities precipitate to the bottom of the glue. Apart from chemical processes, mechanical processes can also be employed. One may purify the glue with mechanical filters, paper filters or bone chars.

To make the glue into various forms, such as brown, white and clear glue, additives must be added. Some of the common additives are Sulfurous acid, phosphoric acid, or alum. To produce school-grade glue, Zinc Oxide is added. At this point, the glue is a weak, runny liquid. Its concentration is increased by placing it in vacuum evaporators and dried via several methods. The glue can be chilled into either sheets or blocks, and then suspended on nets to dry and become even more concentrated. After that, these are poured into different tubes, containers and sticks for commercial use. Glues have played an essential role in history, and will also play a pivotal role in the future. Glues are now taking over other bonding methods, such as stapling, stitching and other forms of fastening things together. It may be easy to overlook the significance of glue, but it truly does help to keep the world together!