Car engines vibrate due to unbalanced forces arising from reciprocating and rotary motion of the engine’s components.

For most of us, a typical day with our car consists of firing it up, shifting gear, and proceeding with our business. As the car burbles to life, we hardly give a second thought to the steady, sometimes imperceptible vibrations emanating from it.

What causes engines to vibrate when starting up or idling? Let’s find out!

Recommended Video for you:

Why Do Car Engines Vibrate Upon Start Up?

Even though we may be seemingly oblivious to in-car vibrations, they are a subtle reminder that the car is running. When faced with a malfunction, one of the most common signs is deviation from this ‘unnoticed’ running vibration.

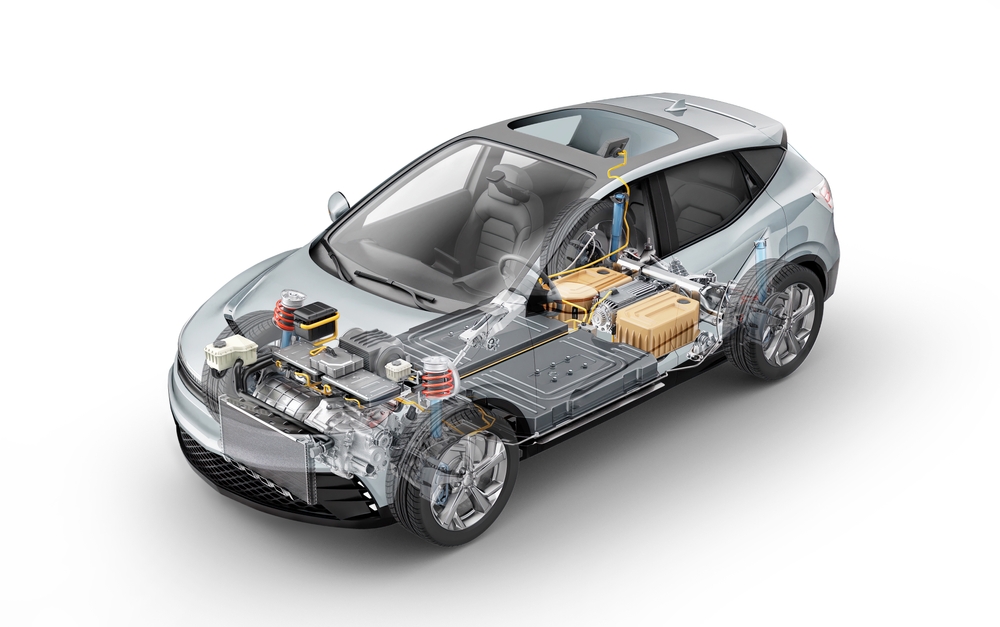

Vibration is often attributed to motion of the drivetrain’s internal components. However, this is only partially true, as electric vehicles, which also have moving internal components (motors), do not exhibit such vibration.

The answer to this conundrum lies in the design of internal combustion engines.

Internal Combustion Engine Design

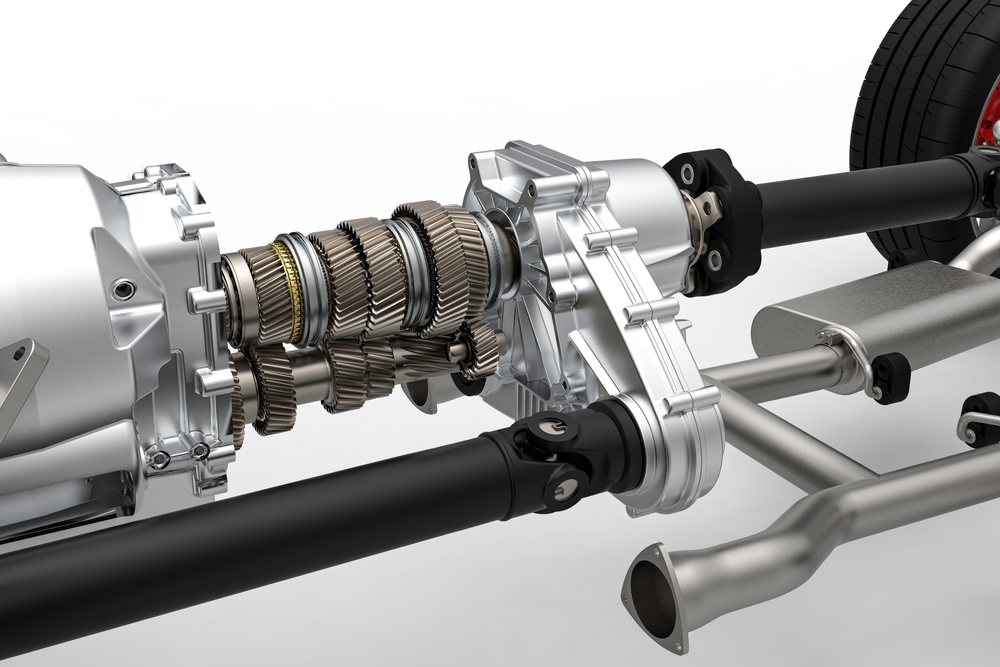

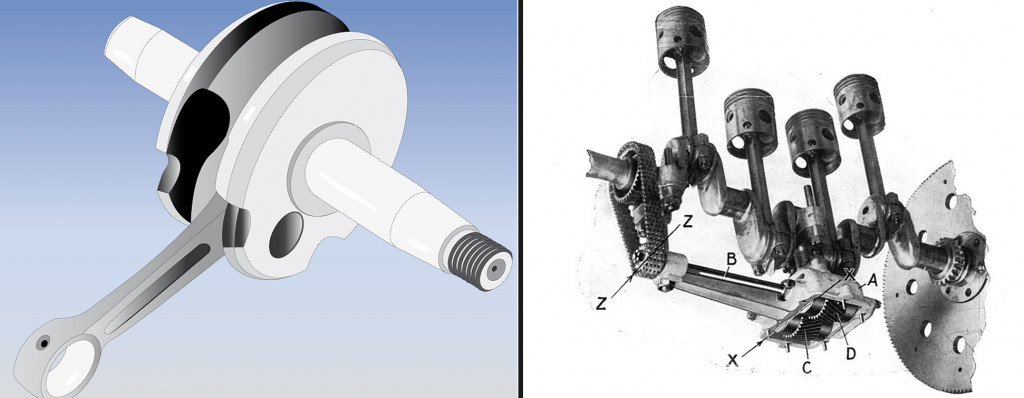

Internal combustion engines are reciprocating engines. They consist of a reciprocating component (piston and connecting rod) to bring about rotatory motion (crankshaft). The combination of reciprocating and rotary motion introduces cyclic and unbalanced forces. These forces are perceived as the vibrations we feel upon starting/running the car.

What Are Unbalanced Forces?

Unbalanced forces are generated when all the forces in a moving system aren’t cancelled out by opposing forces. The residual forces cause various disturbances, in this case – vibrations.

Vibrations In Internal Combustion Engines

Vibrations in cars arise from the reciprocating and rotary motion of the piston, connecting rod, and crankshaft. It is desirable for components to exhibit ‘symmetry’ of forces when in motion. That is to say, both reciprocating and rotary components should be designed so that there are as few residual forces in the moving system as possible. Vibrations in engines primarily arise from two sources.

Static Imbalance

This refers to inequality in the weights and centers of gravity of the various reciprocating components with respect to each other. In an ideal system, these are identical for every piston and connecting rod in the engine.

Dynamic Imbalance

This refers to the presence of eccentric rotational masses that result in the generation of unbalanced centrifugal forces when the engine is in motion. In an ideal system, the center of mass of the rotating elements should lie on the axis of rotation.

Balancing Of Engines

It is important to balance residual forces generated due to the motion of engine components. If unchecked, its debilitating effects include occupant discomfort and complete mechanical failure of the engine. The first step to balancing engines is resolving any static imbalance of machining components to extremely close and identical tolerances. Engineers seek to resolve most imbalance issues by static balancing.

What cannot be resolved by static balancing is addressed by dynamic balancing. Here, unbalanced forces are counteracted by balancing shafts placed opposite to them.

However, it’s important to note that vibration-causing imbalances cannot be completely eliminated from reciprocating engines. They can only be reduced to acceptable levels of mechanical limits and passenger comfort.

Primary And Secondary Balancing

Dynamic balancing is associated with engine run time, and consists of primary and secondary balancing. Primary balancing is done for unbalanced forces acting at the crankshaft’s speed of rotation. Secondary balancing is done for unbalanced forces that act at twice the speed of rotation. The connecting rod, which is longer than the radius of the crankshaft, gives rise to these unbalanced forces. This is known as obliquity. While primary unbalanced forces are greater, they are easier to balance than secondary unbalanced forces.

Balancing In Single-cylinder Engines

Single-cylinder engines are most commonly found in two-wheeled vehicles, such as scooters, mopeds and motorcycles. Due to their design, they can only achieve primary balancing.

The connecting rod’s obliquity causes the motion through the cylinder’s top dead center to be faster than the bottom dead center. This results in the generation of unbalanced secondary forces that result in persistent vibrations, and a relatively less refined design.

Balancing In Multi-cylinder Engines

As a general rule, having a greater number of cylinders is advantageous to balancing an engine. Additional pistons improve the scope for the generation of opposing forces that can cancel out previously unbalanced forces in single-cylinder configurations.

Other than the number of cylinders, their arrangement and firing order is also integral to the engine’s balance. Here are some multi-cylinder layouts and their states of balance.

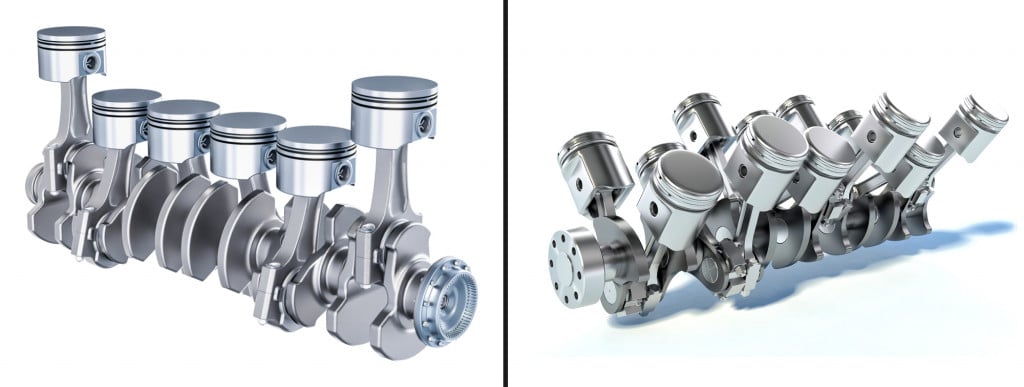

1. Inline 4

The inline 4-cylinder configuration is most common in modern automobiles. By virtue of its layout and the firing order, its primary forces are completely balanced. In contrast, the secondary forces must be balanced using a balance shaft. To prevent secondary forces from exceeding accepted limits, 4-cylinder engines are typically smaller.

2. Inline 6

This engine is one of the most balanced configurations in reciprocating engines. As every piston has its opposing counterpart, it presents a well-balanced set up without the need for balance shafts or large counter-weights.

3. V6

A V6 engine comprises two 3-cylinder banks connected to a common crankshaft. Due to the odd number of cylinders in each bank, these engines suffer from primary imbalance. In order to resolve this imbalance, the angle between the cylinder banks can be changed to produce an optimal setup. Common angles include 60 deg., 90 deg. and 120 deg., 60 deg. being the most balanced layout.

4. V8

V8 engines are a combination of 2 4-cylinder banks angled at 90 degrees. The crankshaft is designed so that two pistons can share one bearing. It also incorporates heavy counterweights to balance the secondary forces. 6- and 8-cylinder engines are commonly found in sports cars.

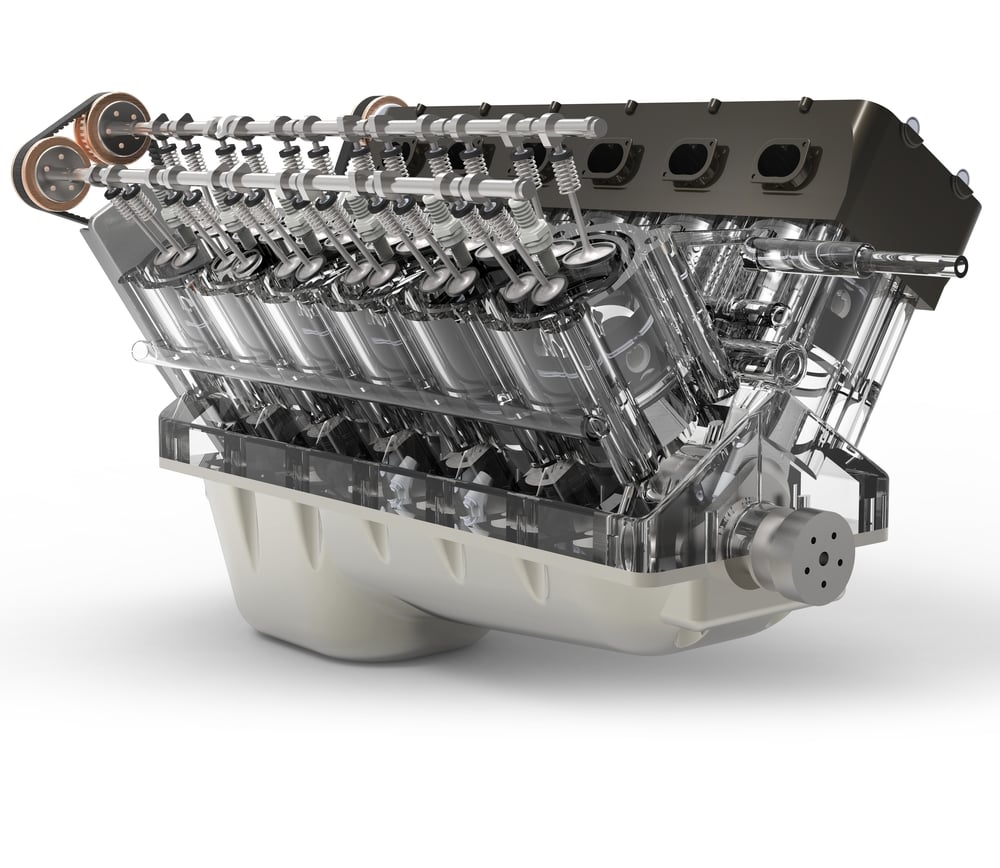

5. V12

A v12 engine can be thought of as a combination of 2 inline 6-cylinder engines, and exhibits superior levels of refinement. V12 engines have very large displacement and find use in powerful sports cars and luxury vehicles.

Importance Of Vibrations In Car Engines

An unwanted change in routine vibrations can signal some sort of mechanical fault or impending breakdown. Engine vibrations and road noise entering the cabin also help the driver establish a connection with the road. This is essential for safety on the road.

This is why many electric vehicles artificially create road noise, in order to replace the stillness of the cabin with typical internal combustion “white noise”.

In pursuit of total quiet, it is possible to look at engine vibrations as a nuisance. However, as enumerated above, engine vibrations have their own subtle role to play.

References (click to expand)

- J KLING. Balancing of Novel Engine Designs. Chalmers University of Technology

- Unit 21 Balancing of Inline and Radial Engines - eGyanKosh. egyankosh.ac.in

- ACS COLLEGE OF ENGINEERING. acsce.edu.in

- https://nitsri.ac.in/Department/Mechanical%20Engineering/MSD_302_Lecture_14_-_Topic__Balancing_of_Rotating_and_Reciprocating_Forces_in_Internal_Combustion_Engines_-_15-10-2020.pdf