Energy recovery systems harness wasted kinetic and heat energy generated from braking, and use it to provide extra power or improved mileage.

Car racing is often looked upon as an exercise in futility – wasting precious resources only to come first in a silly race!

Except that it’s not!

Races are also a huge exercise in research and development, putting everything manufacturers stand for to the test. Still, what if someone wanted to race, while also saving some of those precious resources?

Recommended Video for you:

Can You Drive As Fast As A Race Car And Also Save Fuel?

As per the law of energy conservation, it is abundantly clear, that the total energy in a system remains constant, only changing forms.

However, here is a caveat.

While energy may change forms, it isn’t necessary for these forms to be usable.

For example, consider the motion of a fan after it has been switched off. The fan keeps rotating for a while, expending its residual kinetic energy before slowly coming to a stop.

Another example is a moving vehicle. By itself, it will continue moving until its kinetic energy is no longer sufficient to overcome opposing forces like friction, air resistance, and gravity. Eventually, these will bring it to a stop. If the brakes are applied, this energy is lost as heat, sound and sometimes light. Thus, a conversion of energy takes place, but not necessarily into a form that is useful to us.

Kinetic Energy Recovery – A Way Out Of Energy ‘Wastage’

As the name suggests, kinetic energy recovery is aimed at reducing the amount of energy converted into wasteful, unusable forms. To do so, it takes some of the energy generated by braking and stores it in an accumulator. When needed, this energy is then routed back to the vehicle’s drivetrain in the form of more usable power, without burning more fuel.

This system, called KERS or kinetic energy recovery system, was developed for use in Formula One racing. The stored energy can either be used for additional power for race cars and motorcycles, or to extend range in passenger vehicles and even bicycles.

This extra energy is made available without using extra fuel, making it a sustainable addition to both internal combustion and electric drivetrains. Based on energy accumulation, there are four basic types of KERS:

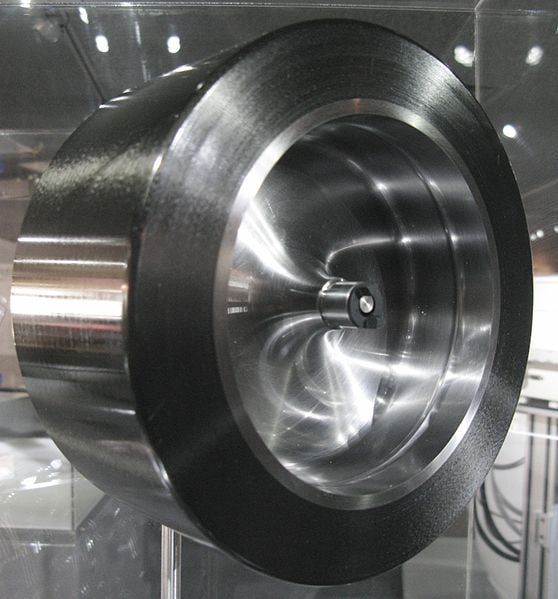

Mechanical KERS

Mechanical KERS make use of a mechanical accumulator in the form of a flywheel, to store some portion of braking energy. This flywheel is distinct from the engine flywheel, and is connected to the wheels using a gearbox of its own.

When the speed has to be reduced, the flywheel is connected to the wheels, causing it to turn. At the start of braking, wheel speed is higher than the flywheel. When the wheels are connected to the flywheel, they lose some of their kinetic energy to it, which is effectively braking. At the end of braking, the flywheel spins faster than the wheels. When this energy is required, the flywheel is connected back to the wheels, releasing the stored kinetic energy.

In order to effect the smooth transfer of energy, wheels and the KERS flywheel are connected by a continuously variable transmission or CVT.

Electrical KERS

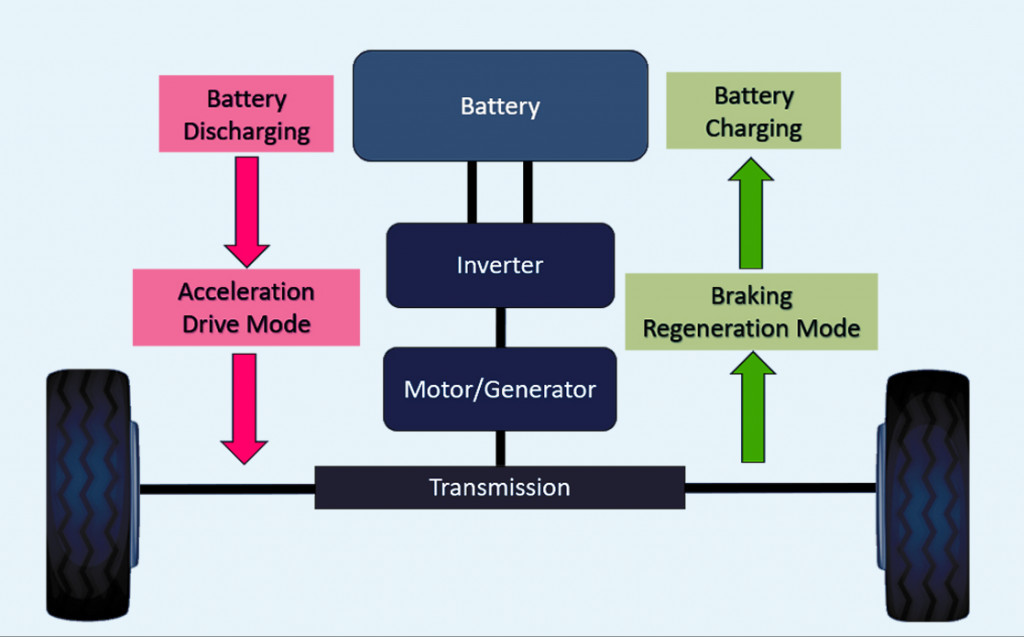

Electrical kinetic energy recovery systems utilize braking motion to generate electricity, which is stored in an electrical accumulator. These accumulators are typically composed of 3 major parts. The first is a motor/generator unit (MGU), that converts the braking energy into electrical energy.

The second part is the PCU, or the power control unit, which is responsible for switching between the flow of current to and from the MGU. The third part is the accumulator itself, such as a battery or a capacitor. Upon braking, the MGU acts as a generator, converting the kinetic energy to electrical energy. It engages a rotor attached with the engine’s crankshaft to move in a magnetic field. This creates electricity that gets stored in the battery.

When the extra power is needed, the PCU switches the direction of current, releasing it from the accumulator and sending it to the MGU. The MGU acts as a motor, supplying the extra power to the engine, without consuming extra fuel.

Hydraulic/Pneumatic KERS

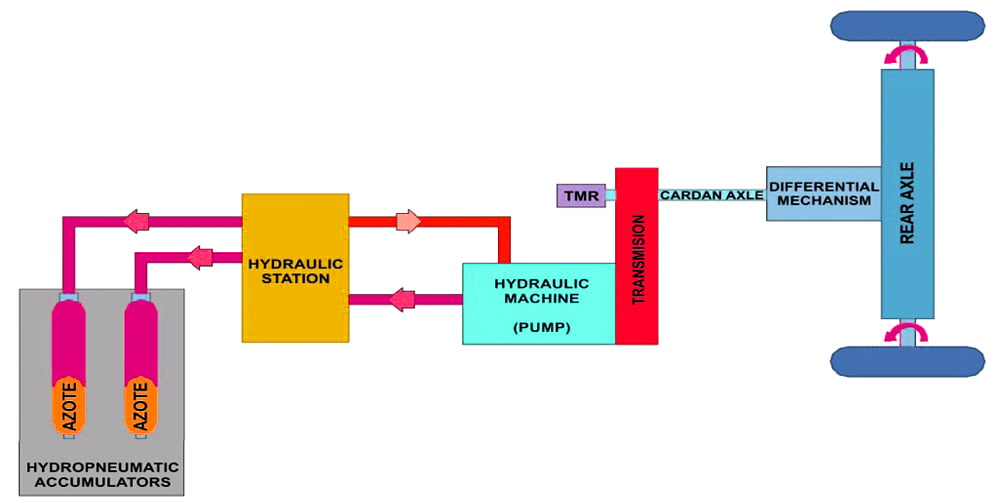

Hydraulic energy recovery systems are very similar to mechanical systems, except for the choice of accumulators. Instead of flywheels, they use fluids, such as oils and gases, to store energy. The system consists of a hydraulic unit that acts like a pump when braking, to compress fluids using the kinetic energy. Upon a surge in power demand, this unit acts like a motor, decompressing the fluid, which releases energy for improving acceleration.

Hybrid KERS

While each of the above-mentioned systems are simple, they can be challenging to implement by themselves in a given motor vehicle. Thus, two or more energy recovery systems are often combined to suit various power requirements.

Advancements In Energy Recovery

Modern energy recovery systems are an iteration of electrical KERS, and include other avenues of waste energy, such as exhaust heat, in their scope. In addition to a motor/generator unit for kinetic energy (MGU-K), they also include a unit for heat energy (abbreviated to MGU-H), that is installed in the engine’s exhaust stream to harness heat energy.

Greater speeds translate to more heat and greater braking forces and consequently, more energy being stored in the ERS. Currently found in F1 cars, these systems are capable of injecting as much as 120 KW (160hp) of power for over 30 seconds in every lap.

Applications Of Kinetic Energy Recovery Systems

Kinetic energy recovery systems were originally designed for race cars with internal combustion engines. Apart from F1 racing, they find use in electric vehicles where brake energy is accumulated to improve the car’s range.

Some systems also convert the braking energy to electrical energy to recharge the car battery and power in-car appliances, such as lights, music system, gauges etc. Bulkier systems, such as mechanical and hydraulic KERS, have been used with great success in commercial transport, e.g., buses and trucks.

Conclusion

Since performance and economy aren’t positively correlated variables, kinetic energy recovery is a great middle ground. Its present versions are rudimentary at best, being deployed exclusively in electric and high-end vehicles. However, such technology holds great promise for the future of sustainable mobility!

References (click to expand)

- Kinetic Energy Recovery System. ijedr.org

- (2013) Comparative Study on Various KERS - IAENG. The International Association of Engineers

- Kinetic Energy Recovery System - ijisrt. ijisrt.com

- K Bopaiah. Energy recovery system for Formula One - 2021 - Bopaiah .... radar.brookes.ac.uk

- K Bopaiah. 2020-01-0545 Strategy for Optimizing an F1 Car's .... radar.brookes.ac.uk

- Prakash, O., Kashyap, I., Kumar, A., Bhushan, B., Kumar, A., & Chouhan, P. S. (2021, March 12). Automobile based heat energy recovery systems. WEENTECH Proceedings in Energy. World Energy and Environment Technology Ltd - WEENTECH.

- Diehl, P., Haubner, F., Klopstein, S., & Koch, F. (2001, March 5). Exhaust Heat Recovery System for Modern Cars. SAE Technical Paper Series. SAE International.

- Kinetic Energy Recovery Systems in Formula 1. Stanford University

- The MGU-K & MGU-H: WHat are they used for and how do .... thef1clan.com

- Cristescu, C., Drumea, P., Ion, D., Dumitrescu, C., & Chirit, C. (2011, August 29). Mechatronic Systems for Kinetic Energy Recovery at the Braking of Motor Vehicles. Advances in Mechatronics. InTech.