Table of Contents (click to expand)

Oil is extracted offshore by drilling into the seabed to access hidden oil reserves. This process is carried out by a team of qualified professionals using specialized equipment. Offshore oil platforms are designed to withstand harsh conditions, such as high winds and waves. There are five main types of offshore oil platforms: rigs, jack ups, spars, semi-submersibles, and drill ships. Life on an offshore oil platform is difficult, with workers often working long hours in dangerous conditions.

Oil is a precious commodity that has caused many conflicts in the past for dominance and control. Oil made company owners like John D. Rockefeller the richest man in America at one point in history. Although the tussle for oil and advancements in the oil extraction process are just a few decades old, oil has been around for millions of years, located deep below the land or sea, where it became trapped and compressed under layers of rocks. Offshore oil is one of the major industries attempting to extract that hidden oil, and is also driven by the incredible potential for revenues and profits.

Recommended Video for you:

History Of Oil Drilling

There are a few records hinting that the Chinese carried out oil drilling as early as 400 AD, but these records aren’t overly credible. The first modern oil-accumulating structure was built in 1897. Three decades later, mobile rigs consisting of a simple barge with a drill mounted on top became a symbol of the rise of Western oil influence for decades to come.

How Oil Drilling Works?

More than 80 million barrels of oil are produced every single day at this point in history. Oil drilling is a process that usually starts with a range of surveys. The popular surveys within this field are geographical, geomagnetic and seismic reflection. These surveys are useful in pinpointing likely areas with substantial deposits of oil. The next stage involves obtaining the necessary permits and abiding by the rules of the region/state/country. Once all the requisite permissions are obtained, the rigs can move in. It requires a team of highly qualified professionals to install and operate these multi-million dollar oil-drilling structures.

You might be surprised to know that there are currently more than 40,000 oilfields worldwide. Most of the drilling takes place on continental shelves—the sunken perimeter of a continent’s true glacial shape. Some of these offshore oil platforms are situated in extremely harsh climates—like the one in the North Sea, which must rigorously withstand 90-knot winds and 20m waves.

Mobile rigs like drill ships are generally reserved for exploratory work. They are often owned by private contractors who then lease them to the oil and marketing companies and make a good amount of money doing so.

Construction And Working

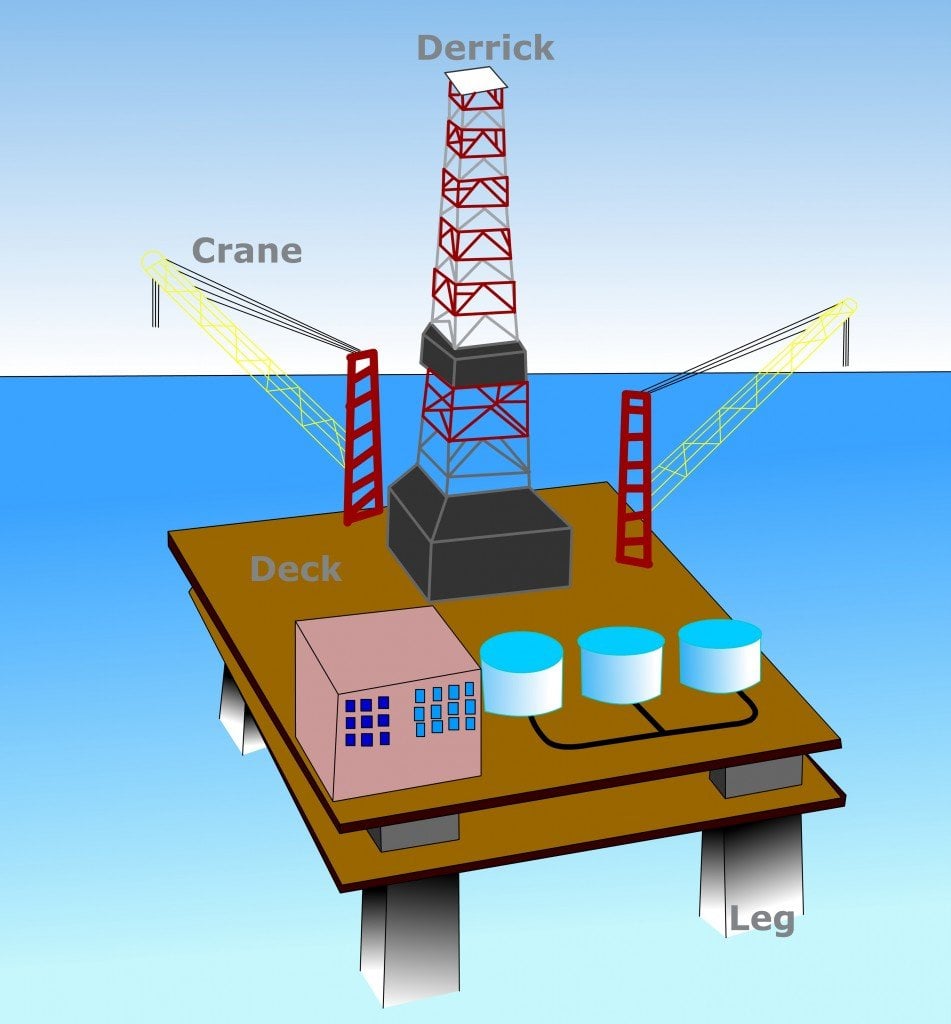

Legs, jacket, deck, derrick and cranes are often the main components/structures of an offshore oil site. Let’s investigate each of these critical parts in a bit more detail:

- Legs: These are the main base on which a rig is held. The main platform of the rig must be able to drill thousands of feet below sea level, which requires stability. Legs are the massive structures that securely anchor to the seabed. Legs are made of concrete/steel structures and are difficult to remove, even if the need arises for them to be relocated.

- Jackets: Jackets are usually vertical steel sections piled into the seabed. They protect the central drill shaft against any damage or interference.

- Deck: The deck is the main working space on the platform, where drilling rigs, production machinery and staff quarters are located.

- Cranes: Cranes are very common on an offshore site. Their main job is to lift and move containers, drilling machinery and sections of piping.

- Derrick: Derricks are usually the tallest structures on an offshore site. A derrick is nothing but a tower to house drill machinery and feed in new pipe lines as the drill descends.

Types

Rigs, jack up, spar, semi-submersibles and drill ships are the five main types of offshore oil types. Let’s learn about each of them in more detail:

- Rig: A rig is the most common type. It is an immovable structure of concrete and steel resting on the seabed. It has deck space for multiple rigs, production facilities and crew quarters. The design philosophy and capital-intensive nature make rigs appropriate for larger offshore deposits.

- Spar: Spars are suitable for many oilfields, such as in the North Sea, where the seabed is not so deep. Spars are drilling platforms affixed to giant hollow hulls that can descend up to 250m – still above the ocean floor – and be secured by cables.

- Jack up: Jack ups are mobile platforms raised above the sea on extendable steel legs. Offshore jack ups are designed for depths of 500m or less. This makes them a more viable option for a small or a mid-sized deposit. The number of crew working on offshore jack ups is much less than that of a rig or spar.

- Semi–submersible: A semi-submersible is usually built on floating pontoons. Their columns are able to sink in the water, where they are anchored to the seabed or kept in place by steerable thrusters. They effectively support drill depths of up to 1,800m. They are semi-mobile and designed for quick deployment.

- Drill ships: A drill ship is a fully mobile oil drilling vessel. It is designed with the purpose of speculative or deep-water mining. These advanced drilling ships are converted to include a drilling platform in the center. They use sophisticated sensors, electronic components and satellite tracking to keep them floating safely while lined up with the well.

Life On An Offshore Site

Life on an offshore site is not easy. Workers/employees need to work almost constantly for up to six months each year. Although oil workers are well compensated, the conditions they work in are undeniably perilous. The good thing is that rigs and spars often come with full facilities, comparable to a cruise ship. This include private rooms for the crew, a cinema hall for entertainment, a 24-hour restaurant to satisfy the hunger pangs of workers anytime, and gyms to keep them fit and fine for such a hectic, physically intensive job. Besides the regular arrival of ships, even helicopters are used to keep the residents of offshore sites happy and provided for at all times. In general, offshore oil sites are better stocked than most other workplaces!

According to a few studies, it is estimated that every offshore worker supports up to 10 more workers in local industries, such as food, transport and maintenance. However, the risk of working there is always looming, considering that offshore drilling involves dealing with highly flammable commodities like oil and gas. Also, these substances are being constantly pumped out at a high pressure during the oil extraction process. A small mistake from any crew member could lead to a catastrophe at the shore site that costs many lives. In case of a calamity, the worst part is that it takes miles for helicopters or ships to reach out for help. Moreover, since workers often need to work for 12 hours continuously on grueling assignments, they are often prone to alcoholism or drug abuse in a bid to manage the stress of this unique and challenging job.