Table of Contents (click to expand)

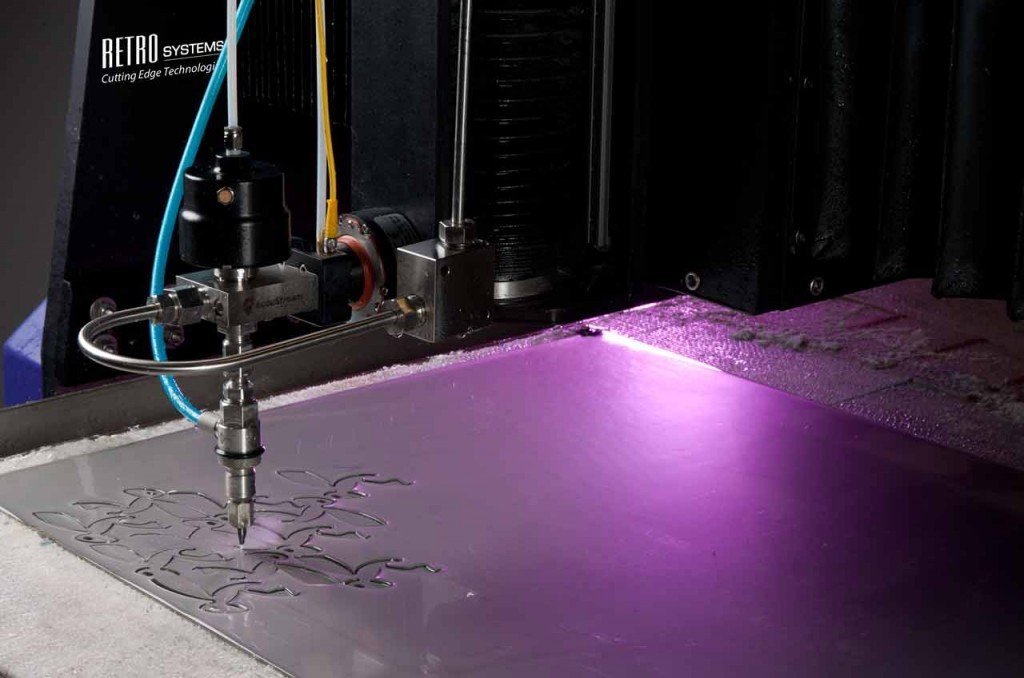

Waterjets are a special tool used at machine shops and consist of a very high-pressure stream of water that is used to cut through metal. The pressure at the mouth of the outlet of the waterjet is 30 times greater than the pressure of water that you see in those hoses used in car washes.

The uses and benefits of water are almost impossible to quantify; apart from the fact that every living thing requires water to stay alive, water is a universal solvent, which renders it extremely functional. You certainly dozens of uses for water, but I can bet that you don’t know about all of its magical traits. For instance, you might have heard (or seen) that water can cut through stones and rocks over time, or even very quickly, but do you think that water is strong enough to cut through things that epitomize strength, like metal?

Recommended Video for you:

Enter Waterjets

The answer, as you may have guessed, is Yes. Water can cut through metals! In fact, it has been used for this purpose for many years now. However, it’s not as though you can spray water on a metal rod and expect it to snap in half; water must be used in a specific way to make it strong enough to be able to cut through metal. This is where waterjets come into play.

A waterjet is a special tool used at machine shops and consists of a very high-pressure stream of water that is used to cut through metal. The pressure at the mouth of the outlet of the waterjet is 30 times greater than the pressure of water that you see in those hoses used in car washes.

If you thought that waterjets were a groundbreaking technique that gained popularity only recently, you’re in for a surprise. Waterjets were first used to mine gold back in 1852 in California; after that, hot water jets were used for extreme cleaning, and about 10 years ago, they started being used as a metal-cutter.

The Key To Cutting Metals

For water, the key to cutting metal is to keep its flow consistent and directed. If it isn’t carefully controlled, it wouldn’t be as effective. Think of cutting a piece of metal with a pleasant sprinkle of water; would that work? No, of course not. You need to have a jet that is channeled through a very narrow nozzle, which can leverage the full pressure of the liquid. The good thing about using water to cut through metal is that, unlike metal-cutters, water does not get overheated and does not pose as many logistical roadblocks. Other metal-cutters were also very expensive and difficult to handle.

Speed Of Waterjets

Waterjets are usually used for softer materials, whereas abrasive jets are used for harder metals. In earlier times, the speed of water leaving the nozzle of an abrasive water jet used to be a whopping 900 miles per hour (roughly 1450 kilometers per hour).

However, equipped with various automated tools of our modern age, the latest abrasive waterjets have a staggering speed of around 3700 kilometers per hour (2300 miles per hour)! Due to this incredible speed, waterjets are able to cut metal within 0.0002 of an inch! Just for a reference of that tiny figure, a typical human hair strand is 0.0004 inches.

Waterjets can cut through metal, stone, marble, stainless steel, granite and wood. Waterjets have been used to remove materials inside train tunnels, bore deep into the ground, create sculptures, and even cut out the parts of a stealth bomber!

You have probably heard about water being so “persuasive” that it finds its way through practically anything, but did you realize that water could be equally ‘penetrative?’ Who knows what wonders water will be able to work for us in the future – provided we still have enough of it around!