Table of Contents (click to expand)

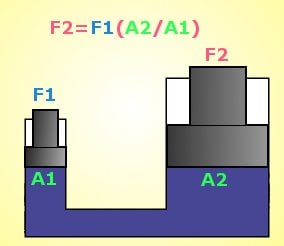

A hydraulic press is a machine that uses Pascal’s Principle to generate a large amount of force. It consists of two cylinders, a smaller slave cylinder and a larger master cylinder. The slave cylinder contains a piston that is used to apply pressure to the fluid inside the slave cylinder. This pressure is then transferred to the master cylinder, where it is pushed by a piston.

If you’ve ever been to a dumpster or industrial area, chances are that you would have come across a hydraulic press. The machines you might have seen are used for crushing cars, molding and casting metal objects, and a whole host of other applications. Any kind of work that involves the application of high pressure over a finite and small area is the perfect job for the hydraulic press. Now, let’s look at what principle the hydraulic press is constructed on.

Recommended Video for you:

Hydraulic Press Works On The Principle Of…

The hydraulic press relies on Pascal’s Principle, which was established by French Mathematician Blaise Pascal in 1647-1648. Pascal’s Principle is a principle in fluid mechanics stating that the pressure at a point has infinite direction, and thus the pressure changed at any point in a confined incompressible liquid is transmitted throughout the fluid, such that the same change occurs everywhere. The principle, when written mathematically, is as follows:

![]()

∆P is the hydrostatic pressure or, more simply put, the difference in pressure of two points within a fluid column. The SI unit for pressure is in Pascals. Here, ρ is the fluid density in kilogram per cubic meter. The term g in the above equation signifies the acceleration due to gravity (measured in meters per second squared). ∆h is the height of the fluid above the point of measurement in the fluid column, which is measured in meters.

The above equation can be very well understood intuitively. The change in pressure occurs due to the change in potential energy of the liquid per unit volume of the liquid, which in turn is caused by the acceleration due to the gravity.

How Exactly Does A Hydraulic Press Work?

Now that we are aware that the hydraulic press is based on Pascal’s Principle, we can move on to the construction and working of the hydraulic press. The components of a hydraulic press include cylinders, pistons, and hydraulic pipes. The working of the press is quite simple and primitive. The system comprises two cylinders that are filled with a fluid. The fluid present inside the two cylinders is usually oil. The fluid (the oil) is filled into the smaller cylinder, which is also known as the slave cylinder.

A piston is inserted into the slave cylinder and pressure is applied. The pressure applied causes the fluid to move through a pipe and into a larger cylinder. The larger cylinder is known as the master cylinder. The pressure exerted on the master cylinder and the piston in the master cylinder pushes the fluid back to the slave cylinder. The force applied on the fluid by the slave cylinder results in a large force, which is experienced by the master cylinder. An industrial hydraulic press comes along with what is known as the press plates. With the help of these press plates, the material to be worked on is either punched or crushed into sheets.

Applications Of A Hydraulic Press

The common use for hydraulic pressing is primarily used for forging, clinching, molding, blanking, punching, deep drawing, and metal forming operations. With the growth and importance of light-weighting in the aerospace and automotive industry, more applications are constantly developing in Thermoplastics, Composites, SMC Sheet Molded Composites, RTM Resin Transfer Molding, GMT Glass Mat Transfer and Carbon Fiber Molding. All of these applications require precise control and repeatability.

Other applications of hydraulic presses include the following:

- It can be used for crushing cars. A hydraulic press is always at the heart of any crushing system. The process involves using a hydraulic motor, which applies a large pressure on the fluids of the cylinders. The fluid makes the pressure plate rise with a great amount of force, which therefore makes the pressure plates crush the car!

- It helps in producing fat-free cocoa powder. When cocoa beans are processed, a liquid known as chocolate liquor is derived. To obtain fat-free cocoa, the liquid is then passed through a hydraulic press, which squeezes out all the fat. After this, the liquid is processed further to make the cocoa powder, which is fat-free.

- It is used in the process of sword-making. This is when sheets of metal are beaten and compressed together. By applying more pressure, they can squeeze more metal into the perfect form factor for the sword. This high density of metals that is compressed into the form of a sword ensures that the sword is durable and does not break under any circumstances.

We can conclude by saying that whenever a large amount of force and pressure is required, hydraulic presses are the best machines to get the job done!