Table of Contents (click to expand)

Nano Technology refers to the method of producing objects whose size range is in nanometers. One nanometer is 10-9 meter, which is one millionth of a meter. Nano structures are extremely complex and find great usage in various fields. With unending potential applications in nearly all spheres of life, it is the technology of today and tomorrow!

Our perception of the world is readily changing for the better. With the onset of newer technologies that are not just environmentally friendly and economically efficient, but also provide far more insight into the molecular nature of things, we are on a path to design ground-breaking systems that operate with incredible speed and will open unseen gateways to mankind’s progress.

Nano technology, or simply ‘nanotech’, falls directly in this exciting category.

With unending potential applications in nearly all spheres of life, it is the technology of today and tomorrow!

Recommended Video for you:

What Is Nano Technology Fabrication?

In the simplest of terms, Nano Technology refers to the method of producing objects whose size range is in nanometers. These objects can go up to several hundred nanometers. One nanometer is 10-9 meter, which is one millionth of a meter. Nano structures are extremely complex and find great usage in various fields.

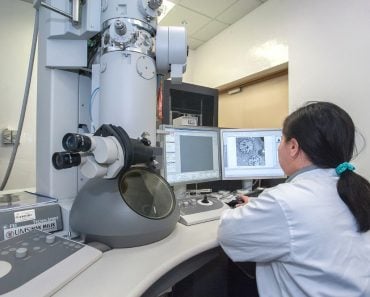

The invention of the scanning tunneling microscope initiated the full-blown study of structures at the nanoscale. Many unclear large-scale phenomena provide greater insight into their working and origin, once the size of the system is decreased exponentially. As they say, the macrocosm reflects the microcosm.

Therefore, nanotechnology helps erase the disparity in accuracy and precision between small and large systems. The 180-degree turn around of properties observed while scaling down the size of the system opens new avenues for further new and as-yet unknown applications.

Nano Technology Techniques

The primary and most trivial distinction between different methods of nanomanufacturing is Top-down vs. Bottom-up methods. Top-down nanomanufacturing involves extracting small nanoscale materials from a larger material by taking out remnants from it until the desired size and properties are received. This category allows for the printing methods of nanotechnology fabrication.

The other method, i.e., bottom-up method is the polar opposite of top-down manufacturing. In this method, objects are built from the atomic or nuclear level and taken up the scale until an appropriate product is extracted.

Top-Down Methods

- Conventional Lithography – This method consists of three steps—coating, exposing and developing. Coating involves a substance called the substrate, along with a polymer layer, which is called resist. Exposing involves exposing the resist to electron beams. Developing involves extracting a positive or negative image from the resist with the help of a chemical substance.

- Photolithography – As is clear from the name, photolithography uses UV rays or X-rays to expose a radiation polymer through a mask. The image shown on the mask is replicated by placing the mask with the resist.

- Scanning Lithography – This method makes use of high-speed electrons and ions to produce the desired patterns on the resist via the mask. The resolution achieved here is greater than photolithography.

- Soft Lithography – This technique uses a mold made of the desired liquid polymer precursor. This method primarily aids in the establishment of large equipment from nanostructures. The biggest advantage of this method is that the mold is usually made of non-toxic substances and can therefore be used from biological nanomaterials.

Nano Top-Down Methods

- Nano-Imprint Lithography – Nano-Imprint Lithography makes the reverse 3D structure of a pre-existing nanomaterial. The object taken is called the master and the process is carried out under very high pressure for the replication process to be precise. This method can be thought of as nanoscale embossing and therefore requires very complex equipment.

- Nano-Sphere Lithography – In Nano-Sphere Lithography, multiple nanospheres are placed together, which ultimately make the ordered pattern on the mask. The mask is placed in a colloid, which is different for each material of the surface object. The empty space among the lined-up nanospheres creates an opportunity to make relatively flat patterns on the mask surface. The holes left on the mask after the process can be used to produce extremely intricate 3D nanostructures and designs.

- Colloidal Lithography – In Colloidal Lithography, electrostatic forces are deployed on the mask in order to produce very complex nanostructures and designs in the form of short hand arrays. This is the only difference between colloidal and nanosphere lithography. Different types of nanostructures can be formed with the help of this method, such as holes, cones and even sandwiches.

- Scanning Probe Lithography – The smallest imaginable tip-like structures on the atomic scale are used to produce images. This method is optimum for the production of high-resolution nanostructures with very complex geometric patterns.

Bottom-Up Methods

- Plasma Arcing – A calculated potential is applied to the electrodes in which a plasma is taken. The gas ionizes and vapors are produced at the two electrodes. This method is primarily used to collect layers on surfaces.

- Chemical Vapor Deposition – The substance that you want to deposit is taken to its gaseous form and then allowed to deposit as a solid on the surface of another object. A flat surface is usually preferred for this process.

- Sol-Gel Synthesis – This process is carried out in the liquid phase. The liquid is then allowed to sit on top of the surface and ultimately becomes more of a gel-like substance.

Significance Of Nano Technology

Medical And Everyday Uses

- used for bacteria-free, stainless and wrinkle-free personal body armor

- used for making water and residue-free thin films for computers, laptops, eyeglasses and cameras

- used in the manufacture of smart fabrics

- can aid in the process of ‘light weighting’ the automobile industry

- has a great role to play in Nano Bioengineering for the conversion of substances into their complex counterparts

- can aid in making powerful batteries and engines for the automobile industry, which also have temperature control

- nanoparticles are used to create special catalysts to boost the speed and productivity of chemical reactions

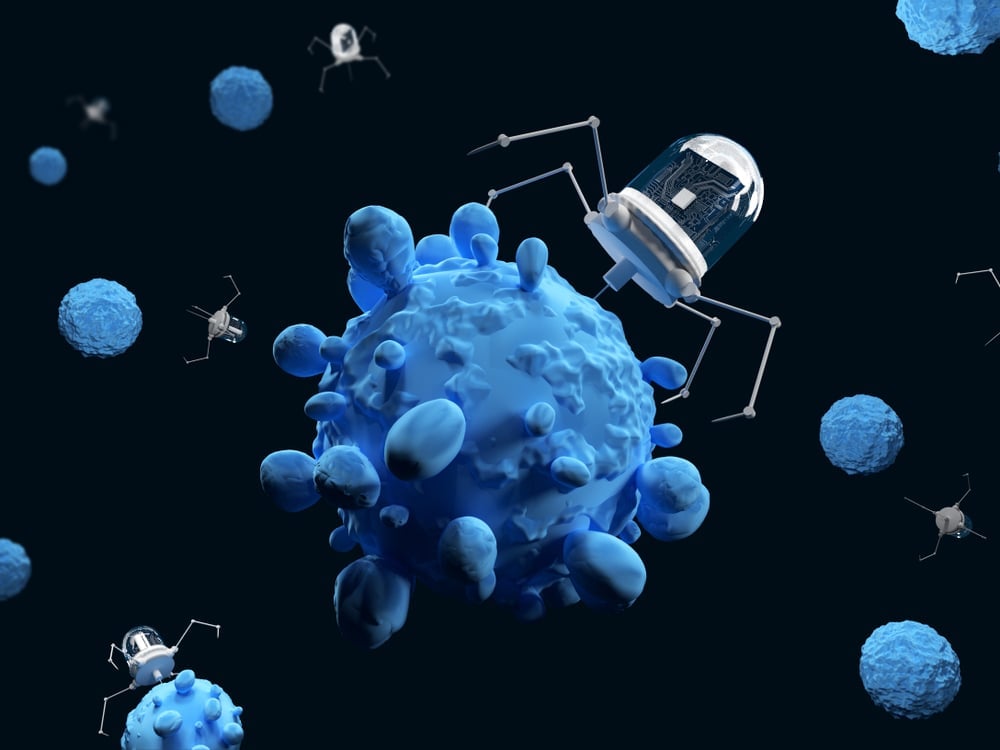

- Potential cancer treatments both in the form of detection and cure are being tested out

- cleaner water can be made easily available with almost no added costs, owing to the high impurity detection property of nanoparticles

Technological Uses

- MRAM computers can be made to boot almost instantly

- High-speed and compact transistors can be made with the help of nanotechnology

- Very high-definition TVs and computers can be manufactured

- Game-changing ultra flexible and foldable screens are the future

- Improved diagnostic care is available

- Helps in the creation of cheaper and more effective molecular novel gene sequencing techniques

- Energy quotient of fuel has increased exponentially

- Cost effectiveness and overall results of solar panels are seeing a significant positive turnaround

Nano Technology is a fairly recent aspect of modern life, but its scope is endless. The vast spectrum of products that can be made or even bettered with the help of this technology is mind-boggling. We can easily mold the properties and underlying characteristics of any given substance to our need. Things can be made for a lower cost, but also at a more advanced level—all at the same time!