Wheel braking is a lever-actuated mechanical or hydraulic phenomenon that employs friction to decelerate a vehicle by resisting wheel motion.

As a child, my worst nightmare was cycling downhill at high speeds, only to hopelessly yank at the handlebars and not slow down in response. A bandaged head and a pit stop at the local mechanic went a long way towards reminding me that brakes are a critical component of any vehicle and must be taken care of accordingly.

Recommended Video for you:

What Is Braking?

To say that one needs to brake for the sake of slowing down or stopping is to only partially understand the function of brakes.

The real function of brakes, much like the function of steering and acceleration, is to control the vehicle in some manner. Apart from deceleration, braking also serves to alter the course of vehicles, such as when making tight turns in motorcycling or drifting and power sliding in cars.

Engine Braking Vs Wheel Braking

The process of retarding vehicular motion can either be achieved internally, i.e., at the power source, or externally, using brakes.

To illustrate this, imagine a cyclist riding on a straight road. In order to keep traveling at a constant pace or accelerate, the cyclist must keep pedaling. However, if he stops pedaling, the cycle will gradually come to halt on its own. This is due to the absence of power working in tandem with various frictional forces to bring the vehicle to a halt. The same phenomenon, when extended to automotive engines, is known as engine braking, and is achieved by not providing any input to the vehicle.

However, if the bicyclist were to encounter a sudden obstacle, he would apply the brakes to decelerate, even though his pedaling has generated enough momentum for the cycle to keep moving. Since the braking happens at the wheel and not the power source, in this case, it is known as wheel braking. In vehicles, this is achieved by pressing on the brake pedal or lever, which in turn actuates the braking mechanisms.

Below, we will discuss wheel braking in detail.

How Do Brakes Work?

Brake architecture is usually mechanical or hydraulic in nature, based on the nature of the application. Even though brake architecture differs amongst vehicles, the braking principle remains the same.

When a brake lever is pressed, a series of linkages move to activate the ‘biting’ mechanism, which consists of friction material. The friction material rubs against the moving wheel to counter its motion, thereby bringing about deceleration.

Components Of A Braking System

1. Lever

In order to activate the braking mechanism of any vehicle, the driver must press a lever. The lever is connected to linkages that carry the driver’s braking input to the biting mechanism. The amount of braking achieved is directly proportional to the pressure applied to the brake lever.

A lever may be hand-operated, such as on a bicycle or the parking handbrake in a car, or foot-operated, which any driver will be familiar with.

2. Brake Booster

A brake booster serves to reduce human effort while applying brakes by amplifying the applied force. This is usually achieved by means of a vacuum that uses hydraulic principles to reduce human effort during braking.

3. Linkages

A linkage connects the lever to the biting mechanism and can either be mechanical or hydraulic in nature. A mechanical linkage is composed of cables that pull to activate the biting mechanism. A hydraulic linkage, on the other hand, comprises a master cylinder that pushes oil to the biting mechanism through fixed or flexible plumbing.

4. Biting Mechanism

The biting mechanism is where the actual braking takes place. Biting mechanisms come in two types: drum brakes and disc brakes.

I. Drum Brakes

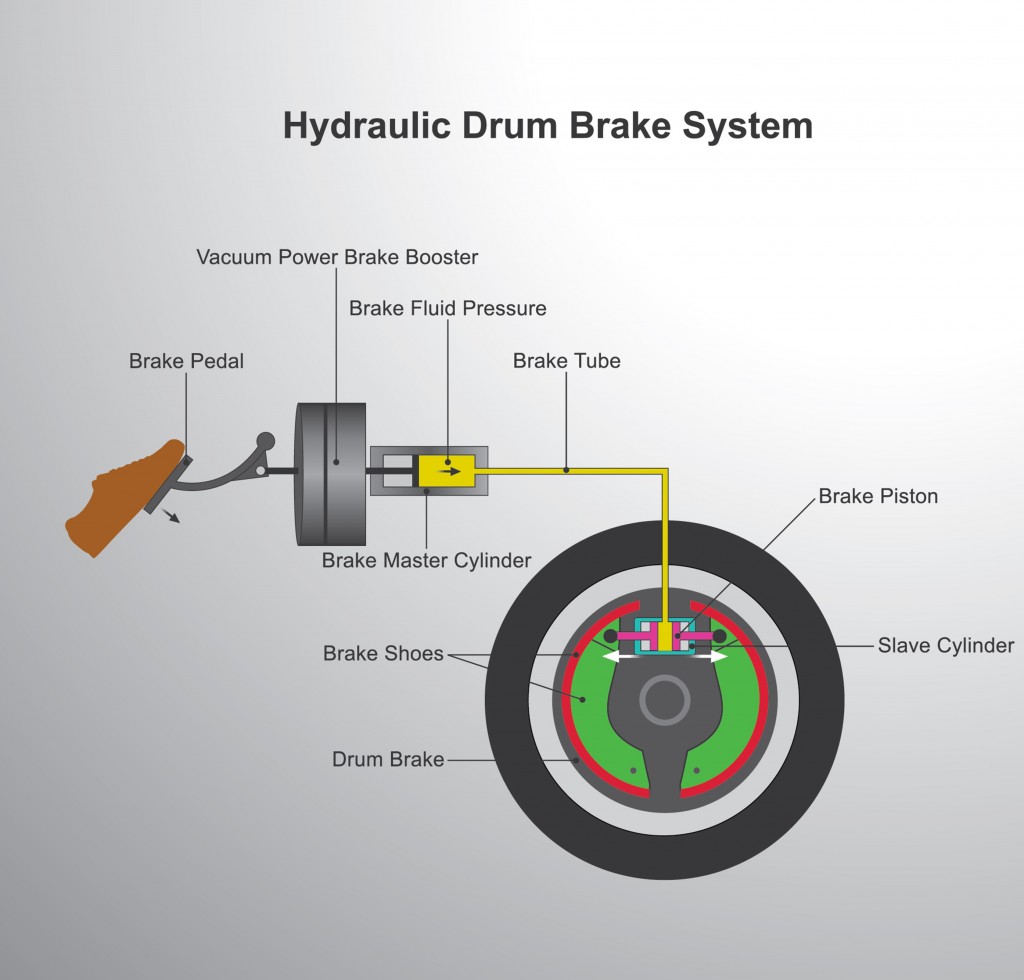

This system consists of a drum attached to the inside of the wheel. Drum brakes can either be activated by a mechanical or hydraulic linkage.

Braking is brought about by fixed brake ‘shoes’ that are lined with friction material and expand to rub against the brake drum. When the brake lever is disengaged, these shoes retract back into position through spring action.

Drum braking is an internal action, as the brake shoes are contained within the drum liner and press outwards. While drum brakes were found ubiquitously in old vehicles, they are employed only for the rear wheels in most modern systems.

Ii. Disc Brakes

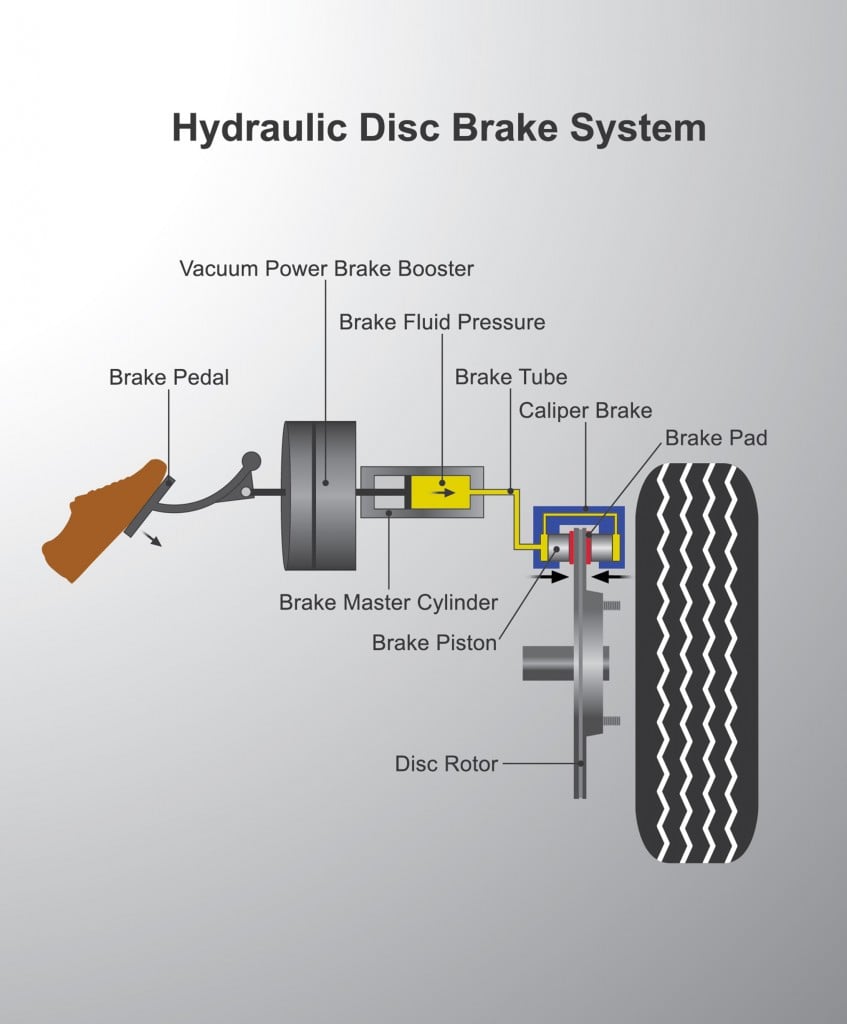

This system consists of a rotor with an overarching unit called a caliper. This caliper houses pistons that push against brake pads, which consequently push against the brake rotor to bring about braking.

Unlike drum brakes, disc brakes are only hydraulically activated. Brake discs are exposed, as compared to drum brakes, which are a closed unit, so there is better heat dissipation and consequently, better braking.

The parking brake, commonly referred to as the handbrake, is a mechanically actuated drum brake and locks the rear wheels. In vehicles with rear disk brakes, the brake rotors are modified to house a drum unit to accommodate the parking brake.

Brake Materials

The selection of braking material must be done keeping wear, heat dissipation and friction in mind. While excessive wear can make brakes uneconomical to change very frequently, poor heat dissipation and friction can result in brake fade—the temporary or permanent loss of braking capabilities.

While old brakes used asbestos, its hazardous nature led to the development of better alternatives. Nowadays, commuter cars have brake pads made of synthetic fiber materials, such as aramid and semi-metallic alternatives, such as metal shavings held together by resin. These usually rub against iron or steel rotors.

High-performance vehicles employ carbon-ceramic rotors, which are superior to conventional materials, but extremely costly to replace.

Advancements In Braking Systems

The development of safety systems, such as anti-lock brake systems and traction control systems, prioritize computer control over braking. This enables appropriate brake force distribution to prevent any loss of control arising from the free spinning of wheels, skidding and brake locking when you are forced to brake hard.

While there are other forms of braking, such as engine braking and electromagnetic braking, at this point, no technology has come close to the effectiveness of friction braking. Brakes are an essential component of all vehicles and shall continue to be so, even once the age of electric vehicles begins!