Table of Contents (click to expand)

Well, a sheep haircut is similar to our haircut but it’s technically called sheep shearing. To shear a sheep basically means to trim the wool from the sheep’s body.

Sweaters, jackets, and other winter wear made from wool tend to be extra warm and cozy. As they are made of natural fibers, they are also gentle on the skin.

Ever wonder what wool actually is and how we obtain it from animals? More importantly, how does this wool get transformed into sweaters and other types of apparel?

Recommended Video for you:

Sheep And Wool

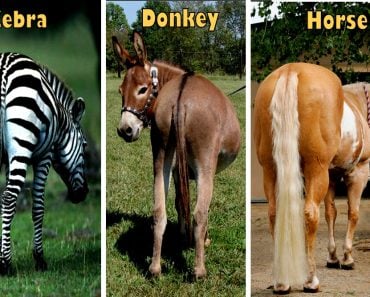

Wool is actually made of the hair (fiber) of animals like sheep (predominantly), alpacas, goats, yak, and even rabbits.

Like other mammals, sheep are covered in hair, but there’s something peculiar about sheep hair. It’s not straight. More importantly, its not too short, which makes it a leader of the wool industry. Sheep are usually covered in thick wool, and their wool tends to be curly and comfy. Sheep’s wool is also pretty good at absorbing moisture and stabilizing the temperature, so it keeps the body comfortably dry and warm during cold weather.

Why Do Sheep Grow Wool?

Sheep grow wool on their bodies to keep themselves warm and protected during bone-chilling winters. In their natural habitat, this wool tends to tangle on fences or low-tree branches and is gradually shed off, meaning that sheep are shedding wool even in their natural habitat.

<h3>How Much Wool Can Sheep Produce?</h3>

They’re naturally adapted to grow more wool as they lose it while grazing. On average, a sheep can produce 2-3 kgs of wool every year.

That’s a whole lot of wool if you can acquire it from large herds of sheep!

When the winter ends and summer begins, sheep don’t really need all that wool to protect themselves, which makes it a good time to pilfer that wool from the sheep, while doing minimal damage to their lifestyle or health.

What Is Sheep Shearing?

Giving haircuts to sheep is an ancient practice. Many of you may also be curious as to how we get the hair off the sheep and how that derived wool is converted into the comfortable woolen sweaters you love to wear in cold weather.

Well, a sheep haircut is similar to our haircut, but it’s technically called sheep shearing. To shear a sheep basically means to trim the wool from the sheep’s body. Normally, the shearer (the person who trims wool off sheep) will shear the entire herd at one time.

A proficient shearer can shear 100+ sheep in a day. This shearing can be done in two ways: blade shearing or machine shearing.

Blade Shearing

Blade shearing involves using a tool similar to a scissor with two blades. The cutting edges (blades) pass each other as the shearer squeezes them together and cuts off the wool (obviously without cutting the skin).

Although it may seem like shearing would be easy, it requires some degree of skill, and importantly, patience. Remember, sheep aren’t really accustomed to getting haircuts like us. Many of them are frightened during the shearing activity.

Thus, a good sheep shearer needs to have compassion for animals and patience when dealing with them.

Blade shearing is a conventional method, but not a very efficient way of removing wool. That’s why shearing is often done by machines, rather than rudimentary blades. That being said, blade shearing is more appropriate for places that experience cold climates throughout the year, because with this method, some amount of wool will remain on the sheep’s body, which bodes well for these colder conditions.

Machine Shearing

Machine shearing is a more advanced and effective method of sheep shearing. In this method, an electric power-driven toothed blade trimmer instrument called a cutter is used to trim wool off the sheep. The shearer carefully drives this cutter back and forth over the surface to trim all the wool from the sheep’s body.

Once the sheep are sheared, they can go back to their usual lives without any complications.

Although blade shearing or machine shearing techniques are usually employed with a shearer operating the respective tool, new technologies are being explored wherein the whole process can be automated using advanced robots!

How Do We Convert Wool Into Clothing?

Now we know how wool is procured from sheep and how we might robotically automate this process in the future, but now the more important question is… what happens to this wool and how does it get converted into apparel?

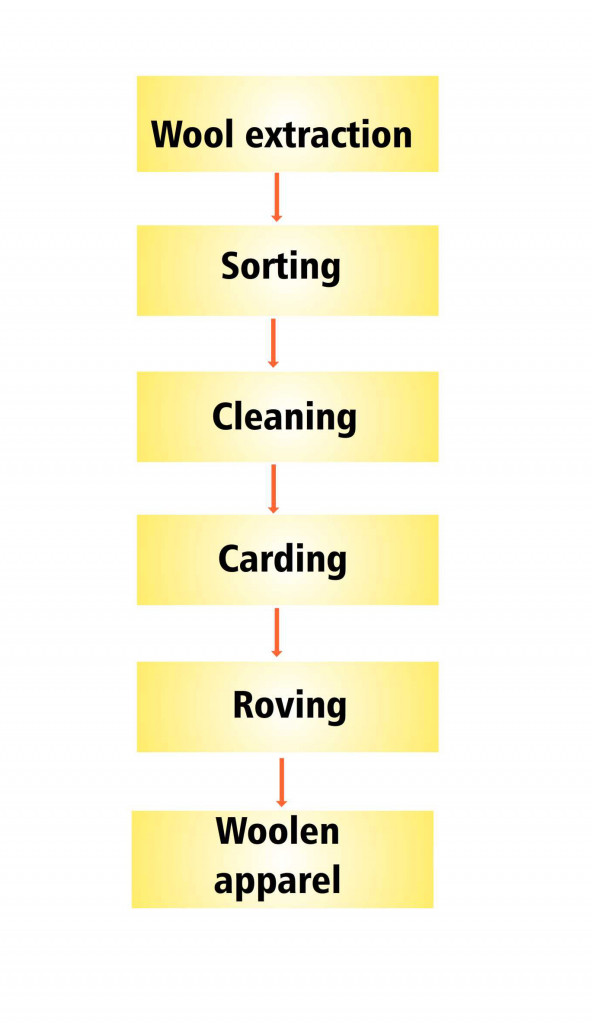

Well, the wool obtained from sheep shearing is taken to a wool factory, technically called a mill. At the mill, wool undergoes several stages of processing before the final woolen wear is knitted. The first stage in this process is sorting.

Sorting

When the wool arrives, it is unclean and messy, so the first step is to sort the wool into different categories. Because the wool derived from sheep is not consistent. Wool obtained from the top and side of the sheep is often long and fine, but the wool obtained from the legs is short and thick.

These different kinds of wool are used to make different types of winter wear. Longer wool is better suited for clothing, while the shorter wool is used for making rugs.

Cleaning

After sorting, wool needs to be cleaned. Sheep, like other herbivores, tend to roam around carefree in the wild, unconcerned about dirt. While grazing, they pass through plants and trees, and while doing so, their wool commingles with leaves, twigs, and even bugs. Now, no one wants these to be in their winter wear, so this sorted wool is thoroughly washed with warm water and soap.

Lanolin: A Good Byproduct

As the wool is washed, dirt and other plant remnants come off. Interestingly, what also comes off during this process is greasy wax called lanolin. Lanolin is secreted by sheep (and other wool-bearing animals) to safeguard their wool and skin. This lanolin is also useful for us, as it forms a key ingredient in hand lotion and various other cosmetics.

Carding

After cleaning and drying the wool, the next step is carding. Carding is done with the help of specialized machines that separate the woolen fiber and straighten it. Any impurities left over (despite washing) are removed at this stage, as the machine pulls out seed, twigs, or other small impurities in the wool.

Roving

Carded fibers are then pulled into long pieces called roving. In roving, these carded pieces are spun together tightly, making a long thin rope of yarn. This allows the wool to be dyed easily (to impart those bright colors!). Once the yarn is ready, it can be used to knit or crochet woolen winter wear, like sweaters!

Although we love wool clothes for keeping us warm, we seldom acknowledge all the hard work that goes in to manufacturing them. In fact, the whole process of making wool clothes is like a giant science project, with people all over the world looking for ways to raise sheep in better ways so that they can produce more wool.

Similarly, as mentioned earlier, engineers are searching for ways to use robots to automate the sheep-shearing process.

Finally, management at mills are always seeking to discover new patterns and designs to make woolen wear even more aesthetically pleasing and comfortable for customers!