Table of Contents (click to expand)

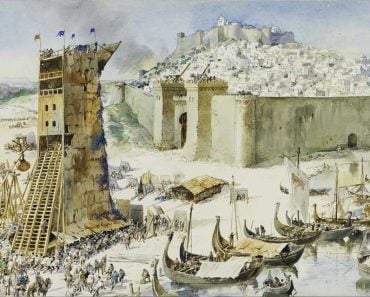

This variety of steel is forged from a specific type of ingot, commonly known as Wootz steel, which comes from the Far East, primarily Sri Lanka and India. The name of the steel, however, is a reference to the city of Damascus, the capital of Syria.

With a name that sounds like it came straight from Game of Thrones, Damascus Steel does have an air of legend surrounding it. For nearly two millennia, the name has been synonymous with high quality and impeccable integrity, some people even suggesting that a finely crafted Damascus Steel sword could split a human hair!

Before you begin an epic quest to secure some of this Valyrian….err, Damascus steel for yourself, it makes sense to understand where this steel comes from, and what has made it so highly sought after and respected for so many years.

Recommended Video for you:

What Is Damascus Steel?

This variety of steel is forged from a specific type of ingot, commonly known as Wootz steel, which comes from the Far East, primarily Sri Lanka and India. The name of the steel, however, is a reference to the city of Damascus, the capital of Syria, where the swords were either sold or directly forged at some time in the past.

What makes this type of steel stand out, particularly when forged into larger items (e.g., swords) is that the appearance of the metal is entrancingly unique, resembling ripples or waves across water. The patterns found on the steel are swirling and textured, yet the metal is extremely strong and difficult to shatter. Perhaps even more importantly, the forging of such metal was known to be quite simple, as the material was quite plastic and malleable when in a superheated form.

While many relics made of Damascus steel have been found, the actual technique that was required to form the ingots remains lost to history. For roughly 1,500 years, a flow of ingots from the east to the west allowed for this remarkable material to spread through the world, but this forging style eventually ran out of favor around the middle of the 18th century.

Today, there are some manufacturers who claim to forge and sell items made of Damascus steel, but “real” Damascus steel is no longer being produced today. In India and other sources of these Wootz steel ingots, their production was variable, meaning that the natural contaminants of the metal would differ. The bladesmiths and ironworkers that received these ingots would then have to work with the raw materials provided, resulting in products of different quality and appearance. In other words, there was no factory churning out identical ingots for western consumption, so as the ironmaking process changed in the east, the flow of ingots that could make Damascus steel similarly dried up.

What Makes Damascus Steel So Special?

The unique origins and journey of Damascus steel makes it historically relevant, but it also had a number of qualities that made it unusually sought after throughout history. Although there isn’t any firm evidence about the exact process of Wootz steel ingot production, it is believed that woody biomass, leaves and other iron alloys were used in the process to carburize the material. By increasing the carbon concentration of the steel (to approximately 1-2%), it would leave behind carbon nanotubes within the metal, which can be derived from plant fibers.

As opposed to other forms of metal in use at the time, Damascus steel also had some degree of hyper-plasticity; this means that the swords forged from this metal were able to bend without breaking, and return to its original form. It was reputed that the edge of such blades could also be refined to an unusually sharp and durable edge. In an age before sophisticated armor, this sort of advantage made this type of steel extremely valuable.

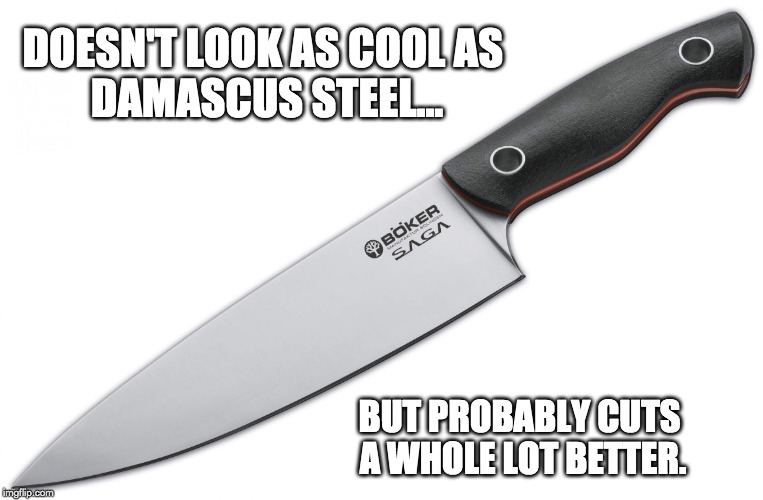

How Does Damascus Steel Measure Up Today?

While this specialized type of steel may have been a huge advantage hundreds of years ago, modern advancements in steel and other high-strength alloys have diminished the appeal of Damascus steel to a mere novelty. For example, the Rockwell Scale is a metric for measuring the hardness of a material, and its ability to withstand load. Damascus steel has a Rockwell hardness of between 30-50, depending on the particular composition of the ingots used. However, even a basic kitchen knife today has a Rockwell hardness in the mid-50s.

Furthermore, most blades made today are stainless steel, meaning that they are far more resistant to corrosion and highly durable, an advantage that Damascus steel did not enjoy. As for the plasticity of the metal, in comparison to traditional iron or steel swords, today’s alloys and stainless steel has a high level of plasticity, allowing the metal to bend, yet still spring back to its original form without losing any of its integrity.

A Final Word

These days, we are easily enamored by things from the ancient past, particularly those objects that have some sort of legendary quality. Whether that is in response to the global obsession with Game of Thrones, or some instinctual nostalgia for simpler times, there’s no denying that things like Damascus steel hold a fascination for us. However, in comparison to the metal that we have developed and commonly use today, this once-prized metal would be deemed less than average, and is truly only desirable for its aesthetic appearance, rather than its function.

References (click to expand)

- Verhoeven, J. D., Pendray, A. H., & Gibson, E. D. (1996, July). Wootz Damascus steel blades. Materials Characterization. Elsevier BV.

- Kochmann, W., Reibold, M., Goldberg, R., Hauffe, W., Levin, A. A., Meyer, D. C., … Paufler, P. (2004, June). Nanowires in ancient Damascus steel. Journal of Alloys and Compounds. Elsevier BV.

- Verhoeven, J. D., Pendray, A. H., & Dauksch, W. E. (1998, September). The key role of impurities in ancient damascus steel blades. Jom. Springer Science and Business Media LLC.

- Damascus Steels.